プラスチック油化装置

サーマリシス

プラスチック廃棄物を価値のある資源に

Wast Plastics Become Valuable Resources

安全で操作も容易、生成された油はそのまま自家消費できる優れた経済性。

Achieving excellent economy by using recycled oil in your own plant,with safe and easy operation

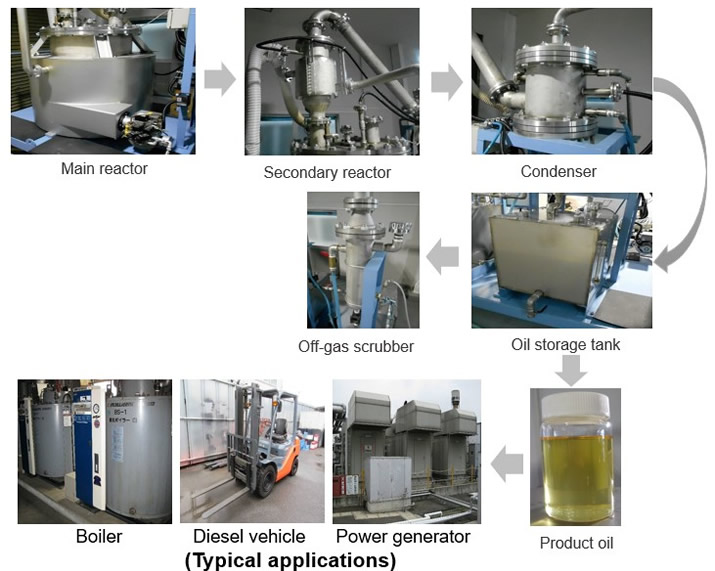

廃棄物となったプラスチックを熱分解して再利用可能な油を生成。油化後の生成油は、ボイラー燃料や発電機の燃料として再利用できます。

By thermal decomposition,the wast plastics can be recycled and reused by creating oil for reuse.The recycled oil can also be used as fuel for power generators and boilers

With the E system,it is possible to produce valuable recycled oil from waste plastics. This recycled oil is suitable as fuel for power Generators or boilers.

油化装置の特徴

〇油化対象樹脂:

ポリスチレン(PS)・ポリプロピレン(PP)・ポリエチレン(PE)〇油化対象外樹脂:

ポリエチレンテレフタレート(PET),アルミ等電蝕金属を含むもの

※塩素系プラスチック(PVC/PVDC/Kコート品等)に関しては別途お問い合わせ下さい。

※その他の油化適合物・不適合物については、お問い合わせ下さい。

〇二酸化炭素の削減が可能です。

〇生成油回収率90%以上。

Key Features of E System

〇Appropriste plastics:

PS,PP,PE

〇Inappropriate plastics:

PET and plastics including Al

※Please make a separate inquiry regarding plstics

containing chloride(ie PVC,PVDC,K-coated materials etc).

※Please inquiry regarding the suitability of other materials.

〇It can reduce CO2 emission.

〇Oil recovery rates are over 90%.

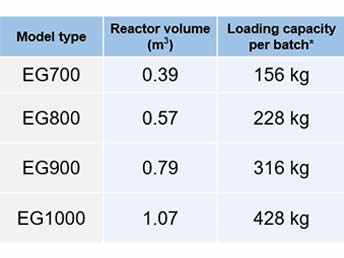

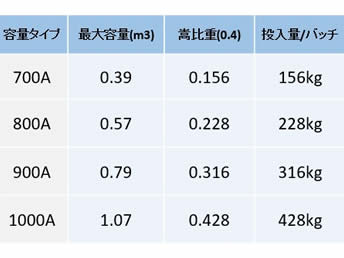

※上記仕様のほか、処理能力に合わせた容量対応が可能です。

※弊社では常に製品改良を心がけておりますので、カタログ記載内容につきましては、予告なく変更する場合が有ります。

※1 It depends on material and operation.

※2 It depends on your country`s low

・We can possible to produce the suitable to your processing capacity.

・Information in this document is subject to change without notice.

Plastic pyrolysis system

Achieving excellent economy by using a product oil in your own plant under safe and easy operation

By thermal decomposition, waste plastics can be converted hydrocarbon oil, which can be used as fuel for a power generator and boiler.

The E system converts waste plastics into hydrocarbon, which can be used as fuel for a power generators or boiler.

Appropriate plastics as feedstock: PS, PP, and PE.

Inappropriate plastics: PET and Chlorine-containing plastics such as PVC, PVDC, and PVDC-coated film.

Please ask us about the suitable plastic type as a feedstock for pyrolysis.

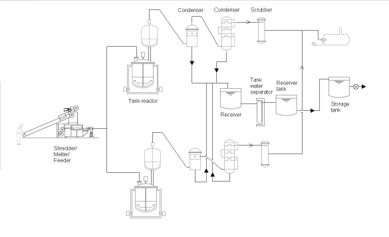

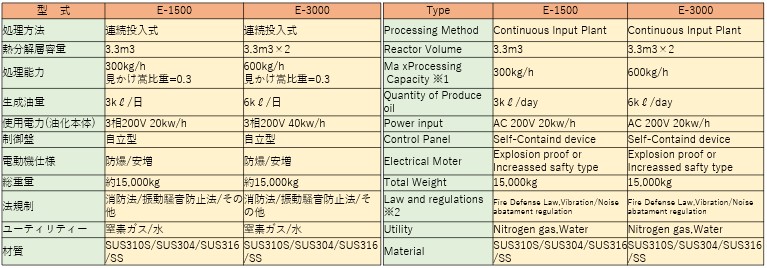

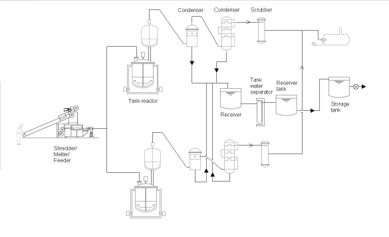

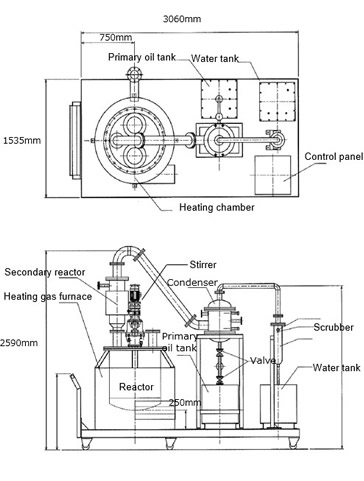

Processing method

Reactor volume

Max. processing capacity

Production rate of oil

Power consumption

Device body weight

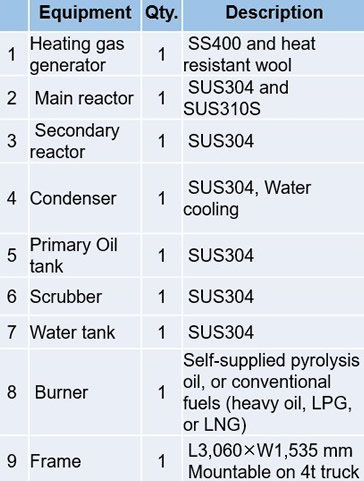

Typical ancillary equipment

Continuous feeding

One unit of 3.3 m3 reactor

300 kg/h

3 kL/day

20 KVA(AC 200 V) Max

Approx. 15,000 kg/unit

Nitrogen cylinder, water line, flare stack

Continuous feeding

Two units of 3.3 m3 reactor

600 kg/h

6 kL/day

25 KVA(AC 200 V) Max

Approx. 25,000 kg/unit

Nitrogen cylinder, water line, flare stack[

Information in this document is subject to change without notice.

*1 Possible to customize a treatment capacity for your necessities.

*2 Depends on local laws and regulations.

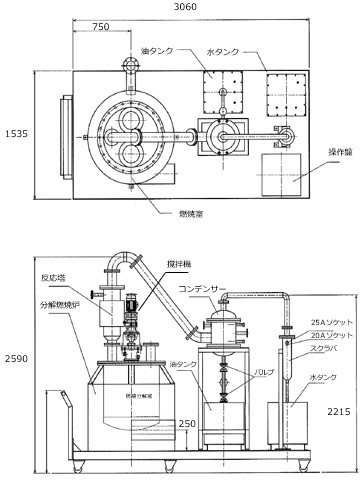

小型油化装置

・大型機導入前のプラスチック成分分析用として

・プラスチックの処理容量が少ない事業所様用として

・大学等研究機関用として

※主電源は、AC100V或いはAC200V

※工事範囲は二次側となります。一次側はユーザー様工事となります。

※上記構成品に含まれない設備については、別途工事費用が発生します。

※諸官庁届けに関しましては、別途お問合せ願います。

Power source is AC100V or AC200V.

Construction range is a secondary works, primary works has to be done by a user.

Equipment that is not in the component list, separate construction fee is required.

Please ask us about the documents needed to submit to the government office.

■高効率・高回収率

プラスチック1㎏から約1ℓ(当社比)の油が回収

できます。油化装置の燃料も生成油を使用するため、

非常に経済的です。

■生成油を電気に変換

回収した生成油1ℓから約3.5kw/hの電源を

得る事ができます。

■環境負荷低減

生成油を再利用する事で環境負荷を低減します。

1kℓ当たり2.71tのCO2が削減可能です。

■対象のプラスチック:PS, PP, PE

■対象外のプラスチック:

PET, PVC,PVDC,PAを含むプラスチック

処理量が約3倍~4倍になります。

For oil sample preparation from waste plastics, prior to introduction of a commercial plant.

For commercial production of pyrolysis oil in a small scale treatment of waste plastics

For academic research

Power source is AC200 V.

For a primary power supply, construction works has to be done by a user.

Our construction range is a secondary power supply.

For equipment that is not in the equipment list above, additional construction fee is charged.

■High conversion efficiency

About 85 wt% of oil is obtained from 1 kg of plastics.

Product oil can be used as fuel for pyrolysis, and thus this system is economical.

■Appropriate waste plastics as feedstock:PS, PP, PE

■Inappropriate waste plastics as feedstock:PET, PVC, PVDC, PA.

We can provide a plant with a continuous feeding equipment. Treatment capacity is increased three to four times than a batch operation using a plant of the same size.